No products in the basket.

Blog

What is an Inspection Chamber? Our Guide.

Inspection chambers, more commonly known to people outside of construction and drainage industries as a manholes, are a vital part of any underground drainage system. They function as an access point, allowing maintenance workers to inspect and clear drains and sort out any blockages. Inspection chambers allow people into the underground system to perform maintenance tasks, so they should always be properly covered with the correct manhole cover. This is especially important, as while some inspection chambers only go a few feet into the ground, some can be many metres deep, and there’s other risks associated with dealing with them too.

Here, we’ll go over some basic information on these important items of the drainage system, as well as the range of different types and classes you can expect to come across online when looking for inspection chambers and their covers.

Where To Use An Inspection Chamber

You’ll need an inspection chamber any time there’s a change in pipe size, a straight run of piping more than 22 metres, when a drain changes direction by more than 30 degrees, and when a branch pipe joins a main drainage run within the drainage system. Essentially, you’ll need one whenever there’s a notable change in the system – you’ve got to make sure that a drainage rod can reach every part of the system so that no blockages are out of reach of maintenance professionals.

Parts For Inspection Chambers

There are a few essential parts to an inspection chamber:

- The inspection chamber / manhole base – this sits at the bottom closest to the drains, and generally comes equipped with a few inlets that you can fit drainage pipe into.

- The inspection chamber riser – this sits on the top of the base and is designed to connect the base to the cover on the surface via rubber seals. Risers come in multiple heights (and are usually easy to cut down yourself) to match the depth of the chamber base.

- The manhole riser seal – the manhole riser seals are required to keep a watertight connection within the manhole base to stop leaks. If the seals are left out, the chamber will not meet UK regulations.

- The access/manhole cover – this is the part you’ll be most use to seeing on streets and in gardens. They’re intended to keep the general public out of the drainage system, and, as you can imagine, they come in a wide variety of shapes, colours, and sizes, and can handle different amounts of weight depending on their class.

Adoptable vs Non-Adoptable Chambers

The terms ‘adoptable’ and ‘non-adoptable’ are basically just talking about the number of locations that an inspection chamber serves. Adoptable chambers are generally there to service two or more places and are connected up to the UK sewerage network. On the other hand, non-adoptable chambers will usually serve one location, which tends to be a domestic property, with the owner holding responsibility for the installation and general maintenance of the chamber.

Plastic vs Concrete Chambers

So, should you look into getting a plastic chamber or a concrete chamber? This is mostly dependent on the size of the chamber itself – chambers above 600x900mm are actually considered man access chambers, while those under are inspection chambers. For a smaller inspection chamber, plastic can be a great choice, as it’s easier to work with than bulky concrete. On the other hand, if your chamber needs to be big enough to fit a person, concrete is likely the more robust option.

Classes of Inspection Chamber Covers

When it comes to manhole covers, there are a few different classes that you can get that suit different uses. Here’s a quick outline of each one, as defined by the BS EN124 guidelines:

- F900 – these have a test load of 90 tonnes, and are used in heavy load areas like airports

- E600 – these have a test load of 60 tonnes, and are suited to places like loading areas and docks

- D400 – these have a test load of 40 tonnes, and are designed for use in areas such as hard shoulders and carriageways

- C250 – these have a test load of 25 tonnes, and can be used in car parks and service stations

- B125 – these have a test load of 12.5 tonnes, and can be installed in domestic driveways and small car parks

- A15 – these are only suitable for pedestrian areas, and have a test load of 1.5 tonnes

You’ll need to use the right kind of cover to meet the regulations for your project. There are also some other factors to consider, such as non rocking manhole types, when you’re looking into meeting the correct standards with your new inspection chamber.

Inspection Chamber Blockages

If your inspection drain has been overflowing, or if you’ve noticed that water is taking much longer to drain away, you might need to sort out a blockage in the system. But unless you’re a qualified specialist, you’ll need to leave this job to the professionals, who’ll use special mechanical equipment with high pressure water jets to clear out the blockage. Make sure to keep an eye out for blockages so you can take care of them before they become a real issue – if left unchecked, a blockage in your inspection chamber can lead to some serious health and safety problems.

Inspection Chamber and Sewer Safety

It’s important to remember that inspection chambers and manholes can be extremely dangerous to work with, and you should never inspect one yourself unless fully qualified. This is because you can run into noxious gases, that can harm or even kill people who breathe them in – so let the specialists handle it, or make sure you have appropriate training.

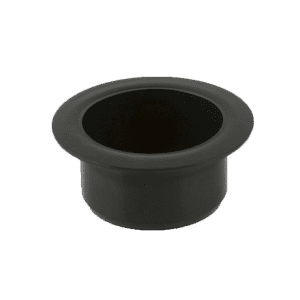

Most manufacturers will sell a reducing ring to fit onto 450mm or 470mm plastic manholes. This reduces the size of the hole at the ground level to stop people or objects from falling inside.

Shop Inspection Chambers

Sale!