No products in the basket.

Blog

Underground Drainage Installation, the basics.

What is Underground Drainage?

Well, pretty much as the name suggests, it’s the drainage system that lives underground. The drainage system is formed from a mixture of lengths of pipe and fittings such as bends, junctions and other fittings to either change direction of the pipe or to adapt to another system. Underground drainage is generally referred to as the sewage system as it is predominately used to transport waste water (grey water) or foul water directly to the sewage treatment facility. This system can also be used for rainwater drainage into a soakaway system or water course.

Usually these days the systems are made from PVC. This is because PVC is a lightweight yet strong material that lasts a very long time and is relatively cheap to manufacture when compared to clay or concrete. Due to it’s light weight it’s also easier to install and it’s almost completely maintenance free. The inner wall is smooth which aids the easy flow of the waste water, and PVC actually has a better “flow rate” than clay or concrete.

It’s easy to spot an underground drainage system as it’ll be terracotta in colour which is the industry standard for this system. Interestingly soil pipes and fittings are almost exactly the same, made from the same machines. The only difference is that these will be black, white or grey in colour and contain a UV additive to protect against sunlight discolouration.

How do you install underground drainage?

Well the trenches must first be dug out to the correct “fall” (to use gravity to move the waste water) then the trenches should be laid with pea shingle (usually 10mm or 20mm) to help protect the pipework. It must also be laid out in the correct way to allow for rodding, testing, cleaning and inspecting the system.

An underground drainage Installation is usually planned out in advance by a drainage engineer with plans drawn out by an architect, but for smaller works the system is simple enough to be installed by a groundworker or general builder, so long as the installation meets the requirements of Approved Document H – Drainage and Waste Disposal.

The fittings and pipework themselves are very easy to join. They’re almost always a “push fit” system, where the pipes come with sockets that include a rubber seal, and the fittings come with either a spigot (which fits into the socket of another fitting or pipe) or a socket (which accepts a spigot).

How do I cut and join the pipework?

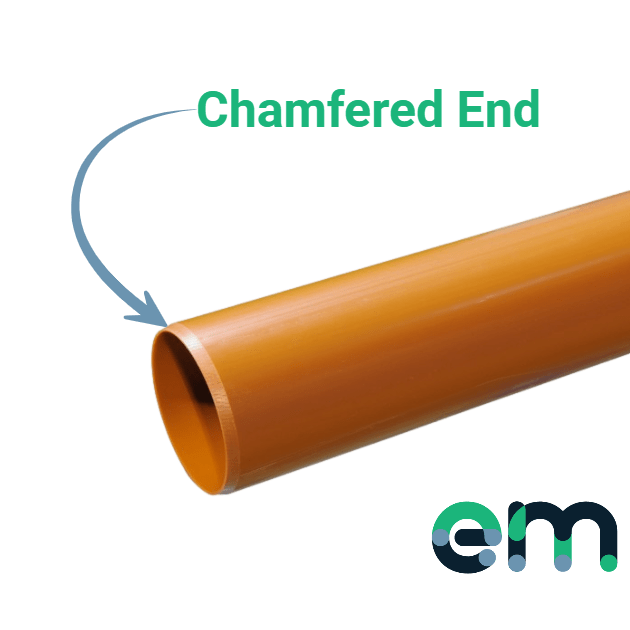

The pipe itself is super easy to cut with either a hacksaw or fine toothed saw, however this will leave the end of the pipe rough or sharp. If it’s left like this, then when the cut end is pushed into a socket it could damage the seal and cause a leakage, which clearly – with foul water – ain’t great!

The way to stop this is to correctly chamfer the pipe using a chamfer tool that will file down and smoothen the end. Then the seal in the socket should be lubricated using proper pipe lubricant. Once this is done ensure that the pipe is located next to the socket and firmly push it in tight until it stops, then pull back 10mm to allow for movement and expansion and that’s it – joint complete. Much easier than a clay or concrete system!

How to lay the underground pipes?

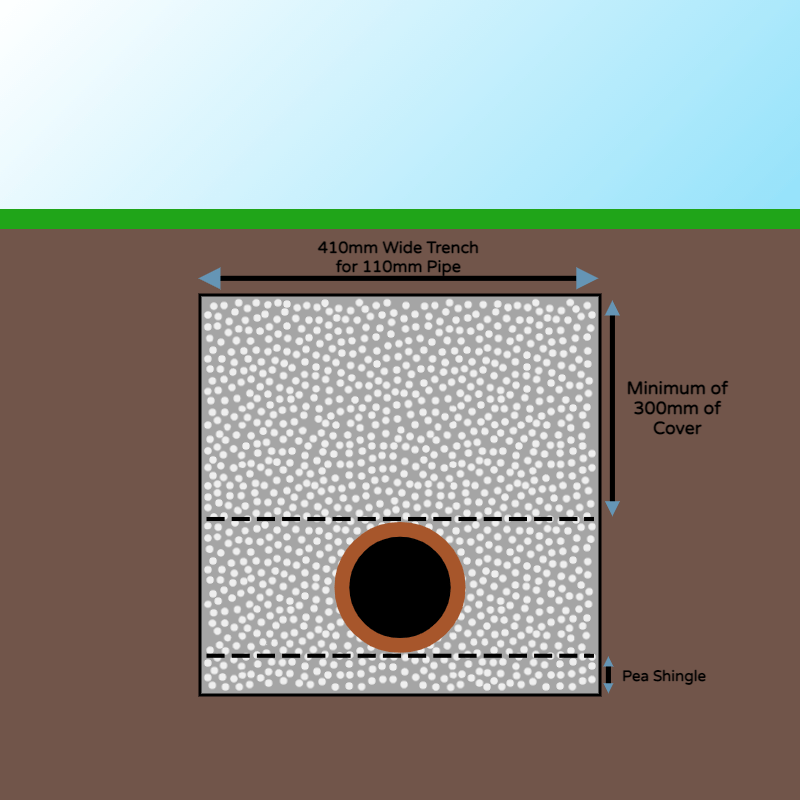

Best practice is to dig the trench and lay pea shingle (10mm / 20mm) in the bottom of the trench, and lay the drainage pipe over the top. Then use more pea shingle for the back fill and side fill so that the pipe is surrounded in the trench. This helps to protect and support the pipework and allow for expansion and natural ground movement. The trench itself should be 410mm wide if using 110mm drainage pipe, or 460mm wide if using 160mm drainage pipe. The trench should always be 300mm wider than the pipe that is to be laid in it. It is possible to use the dug soil from the trench as the side and back fill instead of pea shingle, however it will need to be screened for large stones or rocks and will not be as protective as pea shingle.

When burying the pipework a minimum of 300mm of cover should be put over the top, otherwise when compacting the soil it could damage the pipe system.

If there are areas where the pipework is laid that is likely to be dug up again in the future, either by the homeowner or if more work is to be carried out it is good practise to lay a paving slab over the top, so that any spade or shovel will hit this first and protect the pipe. You can also purchase warning tapes that say “caution sewer pipe below” that will warn anyone digging that there are pipes buried underneath.

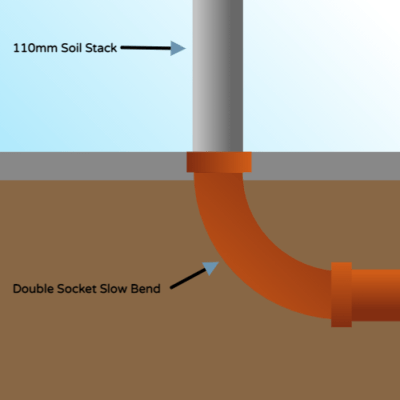

How does it connect to the above ground system?

As mentioned above, the soil pipe systems (the 110mm black, white or grey pipes that run down the side of the house into the underground system) are almost identical, even made from the same machines, so the cutting and jointing process is exactly the same and usually specialist adapters aren’t required.

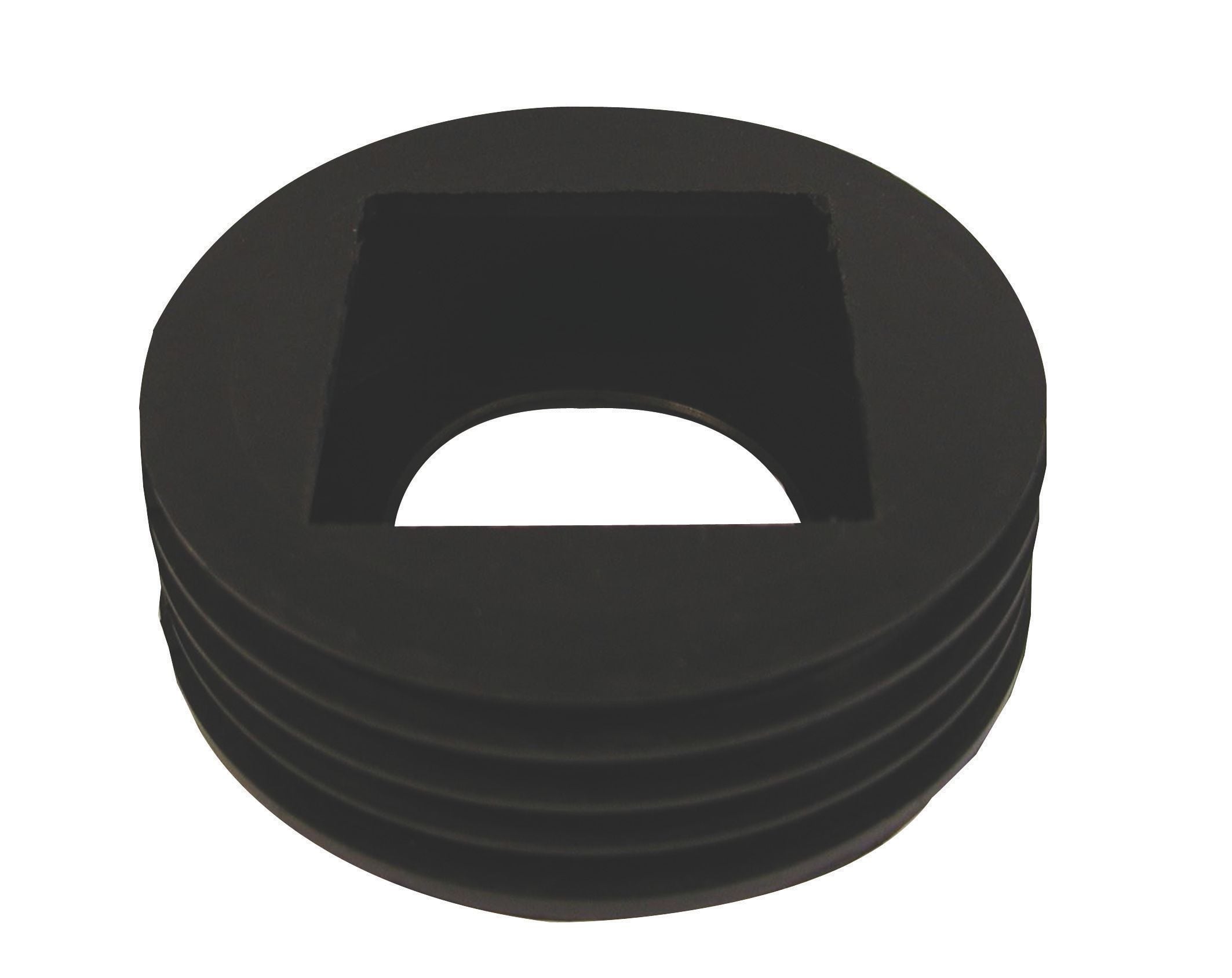

That being said rainwater pipes or waste pipes are slightly different sizes. For rainwater downpipes you’ll need a rubber rainwater adaptor. You’d just push this into the 110mm underground pipe, and then push the downpipe into it. This same adapter can be used for waste pipe systems too, however usually the waste pipe systems would be connected to the 110mm soil pipe further up the run. There are other adaptors available too that are made from PVC and usually come in different colours to match the down pipe.

What fittings are commonly used in the underground drainage system?

- Underground Drainage Pipe – These come in 3m or 6m lengths and often include a socket on the end so that multiple pipes can be connected together easier without requiring additional couplers or joiners.

- Drainage Pipe Bends – These are the fittings you’d used to change direction of the pipe run. They come in different degrees from 11.25 to 90. They come with either one socket (single socket) which has a spigot on one end and a socket on the other, or double socket, which comes with two sockets and no spigot. You can also buy an adjustable bend for awkward angles or just for ease.

- Drainage Pipe Couplers – Also known as joiners, these join two lengths of pipe together. You can buy single socket ones when you need to adapt to a solvent system, or slip couplers w

- Drainage Pipe Junctions – The allow the pipe run to be split into two different runs, or to join two different runs into one. They come as a T junction (a 90 degree turn) or a Y junction (a 45 degree turn). They also come with two or three sockets, called double socket or triple socket.

- Bottle Gullies – These have a grill on top which can accept a rainwater downpipe or waste pipes. They also have a trap built in to stop smells and gasses coming up from the underground drainage system into the building and out of plugholes or air gaps

- Underground Drainage Hoppers – Similar to a gully, these allow the downpipe or waste pipes into the underground drainage system. These however do not come with a trap built in.

- Lowback P Traps – These are usually installed using one of the hoppers above to form the trap which stops foul smelling gasses from entering the property

- Rodding Eyes – These are installed to allow rodding of the system in case of blockages.

- Universal Rainwater Adaptors – These a rubber adapters that allow connection from a rainwater downpipe to the underground system.

- Manhole Bases, Risers and Lids – The manhole base allows connections from the property, or multiple properties to combine into one run to go into the main sewage system. Usually installed at the end of a driveway before going into the road.

Invert levels and falls in underground drainage:

Usually 110mm drainage pipe is laid to a fall of a minimum of 1 in 40. This tends to be the typical for installations of 5 houses or less. This ensures that the flow is great enough to carry the waste and water quickly enough along the pipe that so the chances of a blockage are minimised. The same rule would apply no matter the manufacturer or brand of the system. There are more details in the Approved Document H – Drainage and Waste Disposal document, but if in any doubt consult a drainage engineer or your local authority.

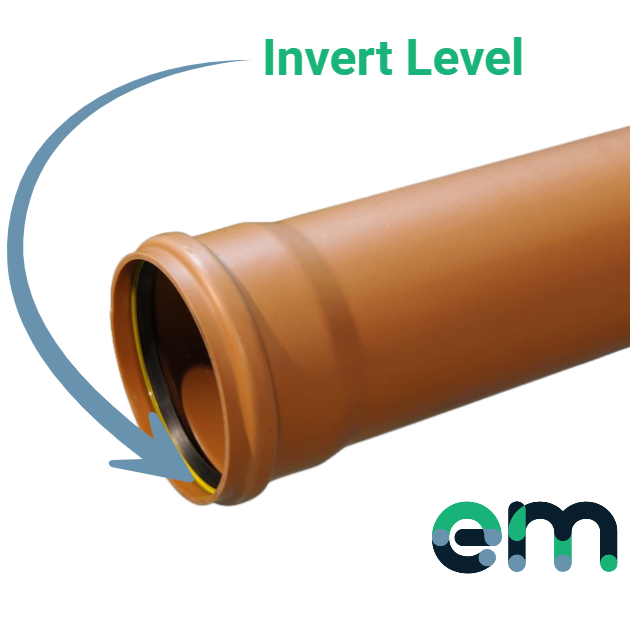

What does invert level mean?

The “invert level” simply means the level of the bottom of the drainage pipe or manhole base outlet. It would be the level at which the water would run. When looking over an architect or drainage engineer’s drawings or plans they’ll usually mention the invert level as well as the cover levels. The invert level is the lowest point within the inside of the pipe, where the water would run.

The cover level simply means the ground level when finished, a good way to remember this is where the manhole cover would go. An invert depth calculation is done by taking these two measurements from the drawings and subtracting the invert level from the cover level. For example, is the cover level is 50 and the invert level is 45 the answer would be 5. (50 – 45 = 5). These calculations and measurements are an integral part of the design and proper functioning of the drainage system.

What are the falls and gradients for underground drainage?

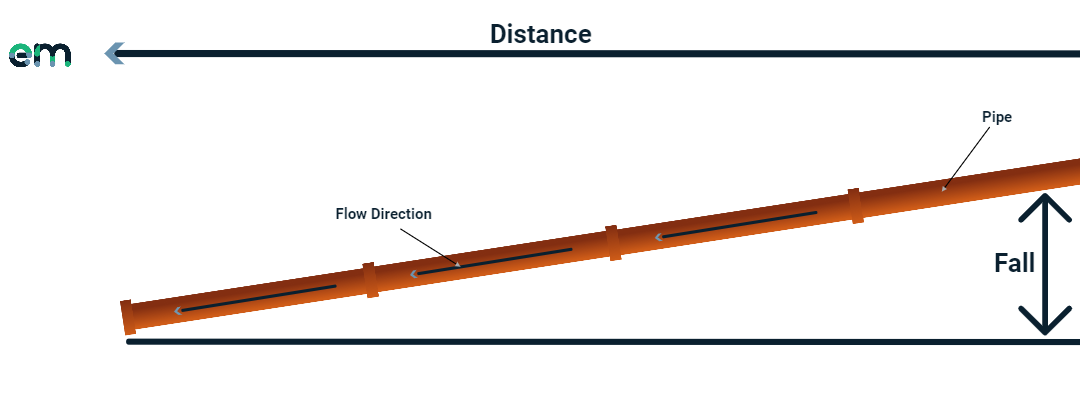

The fall simply means the slope of the pipe. The pipe system needs to be sloped, or have a fall, to allow gravity to move the waste along the pipe. In technical terms, the fall of the pipe represents the angle and distance that the pipe drops vertically along it’s horizontal length. A calculation will need to be done in order to calculate the correct fall to provide adequate flow rates and make sure than any solids or waste do not cause a blockage and that they travel along the pipe quickly enough. The fall simply means the amount the pipe will drop vertically from the start to the end point of the pipe run.

A common fall would be 1 in 40, a “1 in 40 fall” this means that for every 40 measurements of pipe length, it will fall by one measurement. So for a 40m run of pipe, the end of the pipe run one would 1m lower than the start of the run. It doesn’t make any difference which measurement is used, be it meters, centimetres, inches or whatever, the scale and effect is still the same.

Sometimes the fall is referred to as “the gradient” (although less often these days) when calculating a gradient the calculation is slightly different. You’d need to divide the vertical fall by the horizontal length of the pipe run. So in our 1 in 40 example, the calculation would be (1 divided by 40) giving a gradient of 0.025.See the picture below for reference.

The gradient equals the fall distance

For example in a 24 metre section of drainage pipe if you had a fall of 0.30 metres and were asked to calculate the gradient:

- Gradient = 0.30 divided by 24

- Gradient = 0.0125

This can be converted into a gradient written as a ratio or 1

- Gradient = 1 / 0.0125 = 80

- Fall = 1 in 80

The above formula may be rearranged for Fall if the gradient is known:

The fall is the gradient x the fall distance

For example, calculate the fall in a 50 metre section of foul water pipework if the gradient is to be 1 in 80. A gradient of 1 in 80 is converted to a number instead of a ratio.

1 / 80 = 0.0125

Fall = Gradient x Distance

Fall = 0.0125 x 50

Fall = 0.625 metres or 625mm.

Adapting to other materials

You can adapt PVC drainage to clay or cast iron drainage pipes by using rubber pipe connectors which feature a jubilee clip to tighten and adapt to pipes with different wall thicknesses.

How and when to test the drains?

Although it does sometimes depend on the local approving authority, you can reference the Approved Document H – Drainage and Waste Disposal.

What is an OD / ID?

This is a reference to the outside diameter and inside diameter of the pipe. If connecting or adapting onto the pipe the the OD will be the measurement you’d need to go to. To calculate flow rates you’d need to use the ID. The outside diameter minus the inside diameter will give you the wall thickness of the pipe. The inside diameter gives you the amount of space within the pipe. The outside diameter tells you how wide the pipe is overall so that you know the size of the hole you need to drill – etc.

Can I buy this stuff from EasyMerchant?

Yep, and you won’t find it at a better price either!! We buy in huge quantities of this stuff because we can and because of the quantities we buy, we get large discounts which enables us to sell these to you at the same price a national large contractor would buy them for. Lake a look through our underground drainage range here. We sell two brands, Brett Martin which is a well known brand for those who want or need it, and an eco brand which is good enough to do the job, but at a more affordable price.

As always, thank you for reading our guide here at EasyMerchant. If you have any further questions about underground drainage installation you can call me on 01371 850 120, or email at sales@easymerchant.co.uk

Author Bio

Nathan Wilde

Nathan has been in the drainage and plastics industry for over 12 years. Having worked for both builders’ merchants and major manufacturers Nathan has gained a significant amount of industry and product knowledge. Now at EasyMerchant Nathan has dedicated himself to making trade’s people’s lives easier.

As always, this was well explained. Great time reading this one.